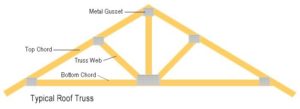

Most roof framing today are pre-manufactured trusses.

Wood (and steel for that matter) trusses are among the most efficient structural components there are. This is due to their shape and construction; and to the extreme competitiveness of the truss industry. There is virtually no extra material in a pre-

engineered roof or floor truss. If, for example, a truss manufacturer used 2×6’s where 2×4’s would work, he’d lose a lot of bids. These structures are carefully engineered. There can be NO STRUCTURAL MODIFICATIONS of any kind to a truss without engineer’s approval. It is common to see these cut, drilled, notched and otherwise modified or repaired. Often engineering is not done and an inspector

should call for proper repairs.

Section 802.10.4 of the 2003 IRC says: “Truss members shall not be cut, notched, drilled, spliced or otherwise altered in any way without the approval of a registered design professional.”

In these cases, a registered engineer in required to specify what repairs are acceptable.

0 Comments